The Ideal Sewing Machine Maintenance Routine

This article explores essential practices for maintaining your sewing machine, ensuring optimal performance and longevity. Discover tips, techniques, and schedules to keep your machine in top shape for all your sewing projects.

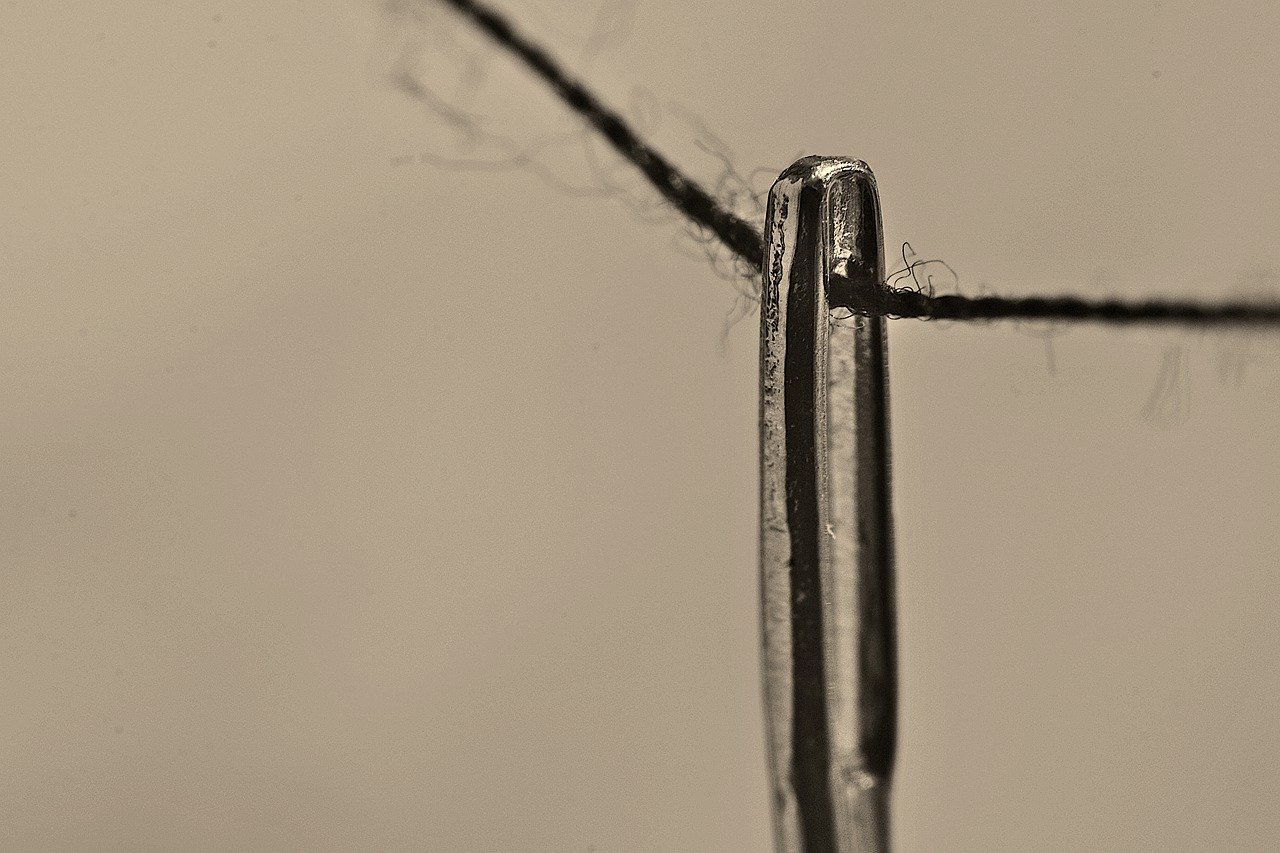

Familiarizing yourself with your sewing machine's components is crucial for effective maintenance. Your sewing machine is a complex piece of equipment made up of various parts, each playing a vital role in its operation. Understanding these components not only enhances your sewing experience but also empowers you to perform routine check-ups efficiently. Key parts include the needle, bobbins, feed dogs, and the presser foot. Each of these elements must be in good condition for your machine to function smoothly. For instance, if the feed dogs are clogged with lint, you might notice skipped stitches or uneven fabric feeding. By recognizing what each part does, you’ll be better equipped to identify what needs attention during your maintenance routine.

Regular cleaning is vital to prevent dust and lint buildup. Just like your car needs an oil change, your sewing machine requires routine cleaning to keep it running like a dream. Dust and lint can accumulate in various parts of your machine, leading to performance issues. To maintain smooth operation, make it a habit to clean your sewing machine regularly. Focus on the bobbin area, feed dogs, and needle plate. Each of these areas can accumulate debris that can hinder your sewing. A quick clean-up every few projects can save you from major headaches down the line!

Using the right tools can make cleaning your sewing machine easier and more effective. Equip yourself with a few essential cleaning tools to ensure your machine stays in top shape. Here are some must-haves:

- Small Brushes: Ideal for removing lint from hard-to-reach areas.

- Lint Removers: These can help clear out fluff that accumulates in the bobbin area.

- Machine Oil: Essential for lubricating moving parts.

Having these tools on hand will make your cleaning routine a breeze and can significantly enhance your sewing experience.

Not all oils are suitable for sewing machines. Using the wrong type can lead to more harm than good! It's essential to choose a high-quality machine oil specifically designed for sewing machines. Apply it sparingly to the moving parts as indicated in your machine's manual. Regular lubrication is crucial for maintaining performance, as it reduces friction and wear on components. Think of it like giving your machine a refreshing drink; it keeps everything running smoothly!

Avoiding common pitfalls can enhance your cleaning routine. Many sewists make the mistake of neglecting the bobbin case or using too much oil, which can attract more dust and lint. It's also important to refrain from using household cleaners, as they can damage the machine. Instead, stick to recommended cleaning products and methods. By being mindful of these common mistakes, you can ensure your cleaning routine is as effective as possible.

Establishing a regular maintenance schedule is key to prolonging your sewing machine's life. Consider implementing a timeline for daily, weekly, and monthly tasks. For instance:

- Daily: Wipe down the exterior and clean the needle.

- Weekly: Clean the bobbin area and feed dogs.

- Monthly: Oil moving parts and check for any wear and tear.

This kind of structured approach will help you keep your machine in optimal condition, ready for any sewing project that comes your way!

Being able to recognize and troubleshoot common sewing machine problems is essential. Every sewist encounters challenges, whether it's a thread jam or skipped stitches. Knowing how to identify these issues can save you time and frustration. For example, if you notice your stitches are uneven, it could be a sign that your needle is dull or that the thread tension needs adjusting. Don't panic! Most issues can be resolved with a little patience and some basic troubleshooting skills.

From skipped stitches to thread jams, here are some frequent sewing machine problems and their straightforward solutions:

- Skipped Stitches: Check your needle and ensure it's properly inserted.

- Thread Jams: Remove the fabric and check for tangled threads in the bobbin area.

- Machine Not Sewing: Ensure the machine is threaded correctly and the presser foot is down.

Empowering yourself with this knowledge allows you to tackle issues confidently as they arise, turning potential frustrations into manageable tasks!

While many issues can be resolved at home, some problems require professional attention. If your machine is making unusual noises or if it’s not sewing at all despite your best efforts, it might be time to consult a technician. Regular professional servicing can also help keep your sewing machine in top shape, ensuring it lasts for years to come. Think of it as a health check-up for your machine!

Proper storage is crucial for maintaining your sewing machine's condition. When not in use, it's important to protect your machine from dust, moisture, and potential damage. A good practice is to cover your machine with a protective cover to keep it safe from environmental factors. This simple step can significantly extend the lifespan of your sewing machine.

Using a cover is an easy way to protect your sewing machine. There are various types of covers available, from simple dust covers to padded ones that provide additional protection. Choose one that suits your needs and fits your machine well. Additionally, consider storing your machine in a dry, cool place to prevent any moisture-related issues.

Seasonal changes can affect your sewing machine's performance. For example, during humid months, moisture can build up in your machine, leading to rust. Conversely, dry winter air can cause parts to become brittle. To combat these effects, regularly check your machine's condition and perform necessary maintenance based on the season. This proactive approach ensures your machine remains in peak condition year-round.

Q: How often should I clean my sewing machine?

A: It’s best to clean your machine after every few projects or at least once a week, depending on usage.

Q: Can I use regular oil for my sewing machine?

A: No, always use oil specifically designed for sewing machines to avoid damage.

Q: When should I take my machine to a professional?

A: If you notice persistent issues like unusual noises or if the machine stops sewing altogether, it’s time to seek professional help.

Understanding Your Sewing Machine

This article explores essential practices for maintaining your sewing machine, ensuring optimal performance and longevity. Discover tips, techniques, and schedules to keep your machine in top shape for all your sewing projects.

Familiarizing yourself with your sewing machine's components is crucial for effective maintenance. Just like a car needs its engine checked, your sewing machine requires regular attention to its various parts to function smoothly. Understanding the anatomy of your sewing machine will enable you to identify what needs maintenance and when.

At its core, a sewing machine consists of several key components, each playing a vital role in the sewing process. Here’s a brief overview of the essential parts:

| Component | Function |

|---|---|

| Needle | Pierces the fabric to create stitches. |

| Bobbin | Holds the lower thread for stitching. |

| Feed Dogs | Moves the fabric through the machine. |

| Presser Foot | Holds the fabric in place while sewing. |

| Thread Tension Dial | Adjusts the tension of the upper thread. |

Each of these components contributes to the overall functionality of your sewing machine. For instance, if the needle is dull or bent, it can lead to skipped stitches, which can be frustrating. Similarly, if the bobbin is not wound correctly, you may experience thread jams. By being aware of these parts, you can perform targeted maintenance and troubleshoot issues effectively.

Moreover, it's essential to understand that different sewing machines may have additional features or components. For example, some machines come equipped with automatic threaders or built-in stitch patterns. Familiarizing yourself with your specific model will allow you to maximize its features while keeping it in excellent condition.

Lastly, don’t forget about the importance of your sewing machine manual. It’s like your machine’s personal guidebook, filled with valuable information about maintenance schedules, troubleshooting tips, and specific care instructions tailored to your model. Keeping it handy will empower you to take charge of your sewing machine's upkeep.

- How often should I clean my sewing machine? It’s recommended to clean your sewing machine after every few projects or at least once a month to prevent dust and lint buildup.

- Can I use any oil for my sewing machine? No, you should use a specific sewing machine oil to ensure proper lubrication without damaging the components.

- What should I do if my machine is making a strange noise? Check for any loose parts, thread jams, or lack of lubrication. If the problem persists, consult a professional technician.

Cleaning Your Sewing Machine

Cleaning your sewing machine is not just a chore; it’s a vital part of keeping your beloved tool in prime condition. Just like a car needs regular oil changes and tune-ups to run smoothly, your sewing machine requires consistent cleaning to prevent dust and lint from accumulating in its intricate parts. Imagine trying to sew a beautiful quilt only to find that your machine is skipping stitches or jamming thread because it’s filled with debris! Regular cleaning can save you from such headaches and ensure that your projects go off without a hitch.

When it comes to cleaning your sewing machine, there are several key areas that you should focus on. The bobbin area, feed dogs, and needle plate are the main culprits for dust and lint buildup. Each of these parts plays a crucial role in your machine's operation, so giving them a little extra attention can make a world of difference. For instance, the bobbin area is where the magic happens; it’s where the thread from the bobbin intertwines with the needle thread to create stitches. If this area is clogged with lint, you might find yourself in a frustrating situation where your stitches don’t form correctly.

To effectively clean these parts, you’ll want to follow a systematic approach. Start by turning off your machine and unplugging it to ensure safety. Then, remove the needle and presser foot for easier access. Using a small brush or a lint remover, gently sweep away any debris from the bobbin area and around the feed dogs. Be careful not to damage any delicate components while doing this. For the needle plate, you might need to remove it entirely to get a thorough clean. Once you’ve cleared away the dust, don’t forget to wipe down the exterior of your machine with a soft cloth. A clean machine not only looks good but also works better!

Using the right tools can make your cleaning routine much more effective. Here’s a quick rundown of essential cleaning tools every sewist should have:

- Soft brush: Perfect for removing lint from hard-to-reach areas.

- Lint remover: A sticky roller can work wonders for quick clean-ups.

- Sewing machine oil: For lubrication, which we’ll cover in the next section.

- Microfiber cloth: Ideal for wiping down surfaces without scratching.

Remember, the right tools can transform a tedious task into a quick and enjoyable routine. So, keep your cleaning arsenal stocked and ready to go!

Now, let’s talk about lubrication. Not all oils are created equal, and using the wrong type can lead to more harm than good. Always opt for sewing machine oil, which is specifically formulated for this purpose. It’s lightweight and won’t gunk up your machine like other oils might. To apply it, use a dropper to place a small amount on the moving parts, such as the gears and the needle bar. This will help to keep everything running smoothly and prevent wear and tear.

Even seasoned sewists can fall into common cleaning traps that can lead to issues down the line. Here are a few pitfalls to avoid:

- Neglecting the bobbin area: Out of sight, out of mind can lead to big problems.

- Using the wrong cleaning tools: Avoid abrasive brushes that can scratch surfaces.

- Over-oiling: Too much oil can attract more lint and create a sticky mess.

By being aware of these mistakes, you can enhance your cleaning routine and keep your sewing machine in excellent shape for years to come!

Tools for Cleaning

When it comes to maintaining your sewing machine, having the right tools at your disposal can make all the difference. Think of cleaning your machine as giving it a refreshing spa day—after all, it works hard for you! To ensure your sewing machine remains in optimal condition, you should gather some essential cleaning tools that will help you tackle dust, lint, and any other pesky debris that might accumulate over time.

First and foremost, a soft brush is a must-have. This tool is perfect for gently sweeping away lint and dust from the delicate parts of your machine, such as the feed dogs and bobbin area. You want to avoid using anything too abrasive that could scratch the surfaces—so a soft bristle brush is ideal. You can often find these brushes in sewing supply stores or even as part of a sewing machine maintenance kit.

Next on your list should be a lint remover. These handy tools come in various shapes and sizes, but their primary function is the same: to catch and eliminate stubborn lint that your brush might miss. A lint roller or a small handheld vacuum can also work wonders in keeping your workspace and machine clean.

Additionally, you’ll need sewing machine oil for lubrication. This is crucial for keeping your machine running smoothly. However, not just any oil will do! You need to use a lightweight sewing machine oil specifically designed for this purpose. Applying the right oil at regular intervals helps prevent rust and ensures that all moving parts glide effortlessly.

Lastly, you might want to consider investing in a microfiber cloth. This cloth is excellent for wiping down the exterior of your sewing machine, keeping it shiny and free from fingerprints and dust. Microfiber is gentle enough not to scratch surfaces while being effective at picking up dirt.

In summary, the essential tools for cleaning your sewing machine include:

- Soft brush

- Lint remover

- Sewing machine oil

- Microfiber cloth

By keeping these tools handy, you’ll find that maintaining your sewing machine becomes a breeze. Just like any other equipment, a well-cared-for sewing machine will reward you with better performance and longevity, allowing you to focus on what you love most: creating beautiful projects!

Q: How often should I clean my sewing machine?

A: It's recommended to clean your sewing machine after every project or at least once a month if you sew regularly. This helps to prevent dust and lint buildup, ensuring smooth operation.

Q: Can I use regular oil for my sewing machine?

A: No, it's best to use oil specifically designed for sewing machines. Regular oil can clog the machine and damage it over time.

Q: What should I do if my sewing machine starts making unusual noises?

A: Unusual noises can indicate a need for cleaning or lubrication. Check for lint buildup, and ensure all moving parts are properly oiled. If the noise persists, consult a professional technician.

Q: Is it necessary to cover my sewing machine when not in use?

A: Yes, covering your sewing machine protects it from dust and potential damage, prolonging its lifespan and maintaining its performance.

Choosing the Right Oil

When it comes to keeping your sewing machine in peak condition, choosing the right oil is absolutely crucial. Not all oils are created equal, and using the wrong type can lead to more harm than good. So, what should you look for when selecting oil for your beloved machine? First off, you want to ensure that the oil is specifically designed for sewing machines. This means it should be sewing machine oil, which is typically a lightweight mineral oil. Avoid using cooking oils or other household oils, as they can gum up the internal mechanisms and lead to costly repairs.

Now, how do you apply this oil? It's not just about slapping it on anywhere you think it might help. Instead, you should focus on key areas that require lubrication. These include the following:

- Needle bar - A little oil here can help the needle move smoothly.

- Bobbin case - Lubricating this part ensures that the thread feeds evenly.

- Feed dogs - Keeping these parts oiled will help your fabric move through the machine effortlessly.

It's also important to note that the frequency of oiling depends on how often you use your machine. If you're a daily sewist, oiling your machine every few projects is advisable. On the other hand, if you're more of a casual user, oiling it once a month should suffice. Remember, a well-oiled machine not only runs smoother but also lasts longer, making it a vital part of your maintenance routine.

Lastly, always refer to your sewing machine's manual for specific oiling instructions. Different brands and models may have unique requirements, and following these guidelines will help you avoid any mishaps. In summary, choosing the right oil and applying it correctly is a small yet significant step in ensuring your sewing machine remains a reliable companion for all your creative endeavors.

Common Cleaning Mistakes

When it comes to maintaining your sewing machine, cleaning is one of the most critical tasks. However, many sewists, whether beginners or seasoned pros, often fall into common traps that can hinder the effectiveness of their cleaning routine. One major mistake is neglecting the bobbin area. This part of the machine is notorious for collecting lint and dust, which can lead to thread jams and skipped stitches. Make it a habit to check and clean this area regularly; it’s like giving your machine a breath of fresh air!

Another common blunder is using the wrong cleaning tools. Some people think that any old brush will do, but using harsh bristles can scratch delicate surfaces. Instead, opt for a soft brush specifically designed for sewing machines. Additionally, many sewists overlook the importance of lubrication. Failing to apply the right oil or forgetting to lubricate altogether can lead to unnecessary wear and tear on your machine’s moving parts. Just like your car needs oil to run smoothly, your sewing machine thrives on it!

It’s also crucial to avoid excessive cleaning. While it might seem like a good idea to go all out, over-cleaning can actually wear down components over time. Stick to a routine that includes regular cleaning without going overboard. Lastly, don’t forget to read your machine’s manual! Many sewists skip this step and miss out on valuable tips specific to their model. Your manual is like a treasure map; it holds the secrets to keeping your machine in tip-top shape.

To summarize, here are some to avoid:

- Neglecting the bobbin area

- Using the wrong cleaning tools

- Skipping lubrication

- Over-cleaning

- Ignoring the machine's manual

By being mindful of these common pitfalls, you can enhance your cleaning routine and ensure that your sewing machine remains in excellent working condition. Regular maintenance not only prolongs the life of your machine but also enhances your sewing experience, allowing you to focus on what you love most—creating beautiful pieces!

Q: How often should I clean my sewing machine?

A: Ideally, you should clean your sewing machine after every project or at least once a week if you sew frequently. This helps prevent lint buildup and keeps your machine running smoothly.

Q: Can I use regular oil for my sewing machine?

A: No, you should use oil specifically designed for sewing machines. Regular oils can damage the machine's components and affect its performance.

Q: What should I do if my machine starts making unusual noises?

A: If your sewing machine emits strange noises, it could be a sign of a problem. First, check for any lint or thread caught in the mechanism. If the noise persists, it’s best to consult a professional technician.

Q: Is it necessary to cover my sewing machine when not in use?

A: Yes, covering your sewing machine helps protect it from dust, moisture, and accidental damage. It’s a simple yet effective way to prolong its life.

Q: What are the signs that my sewing machine needs professional servicing?

A: If you notice persistent issues like skipped stitches, thread jams, or unusual noises that you can’t resolve through regular cleaning, it’s time to seek professional help.

Routine Maintenance Schedule

Establishing a regular maintenance schedule for your sewing machine is essential for ensuring its longevity and optimal performance. Just like any other tool, your sewing machine thrives on consistent care. Think of it as a relationship; the more attention you give, the better it responds! So, let’s dive into a practical routine that you can easily incorporate into your sewing habits.

First off, let’s break it down into daily, weekly, and monthly tasks. Each of these time frames has specific duties that will keep your machine running smoothly and efficiently. For daily maintenance, it’s crucial to clean the area around the needle and the feed dogs after each sewing session. This simple act prevents lint and dust from accumulating, which can lead to performance issues down the line.

Next, on a weekly basis, you should perform a more thorough cleaning. This includes removing the bobbin case and giving it a good wipe down. You can use a soft brush or a lint remover to clear out any stubborn debris that may have settled in those hard-to-reach spots. Additionally, check and replace the needle if it shows signs of wear, as a dull needle can cause skipped stitches and frustration.

Now, for the monthly tasks, it’s time to take a deep dive into your machine. This is when you should lubricate the moving parts with the appropriate sewing machine oil. Remember, not all oils are created equal—so make sure you’re using one that’s specifically designed for sewing machines. Apply a few drops to the designated areas as outlined in your machine’s manual, and you’ll keep everything running smoothly. Also, inspect the belts and gears for any signs of wear and tear, as catching these issues early can save you from costly repairs later.

To help you visualize this routine, here’s a simple table summarizing the maintenance tasks:

| Frequency | Tasks |

|---|---|

| Daily |

|

| Weekly |

|

| Monthly |

|

By following this structured maintenance schedule, you not only enhance the performance of your sewing machine but also extend its lifespan significantly. Just imagine how much more enjoyable your sewing projects will be when you know your machine is in top-notch condition! So, grab that cleaning brush and get started—your sewing machine will thank you for it!

Here are some common questions that sewists often have regarding their sewing machine maintenance:

- How often should I clean my sewing machine? It’s best to clean your machine daily after each use to prevent lint buildup.

- What type of oil should I use for my sewing machine? Always use a sewing machine oil that is specifically designed for your type of machine; avoid household oils.

- When should I seek professional help? If you notice persistent issues like unusual noises or if your machine is not sewing correctly after cleaning, it’s time to consult a technician.

Identifying and Troubleshooting Issues

Understanding how to identify and troubleshoot issues with your sewing machine can save you a lot of time and frustration. Imagine you're deep into a sewing project, and suddenly, your machine starts acting up. Instead of panicking, having a solid grasp of common problems can empower you to fix them quickly and get back to your creative flow. In this section, we'll explore some typical issues you may encounter and how to resolve them effectively.

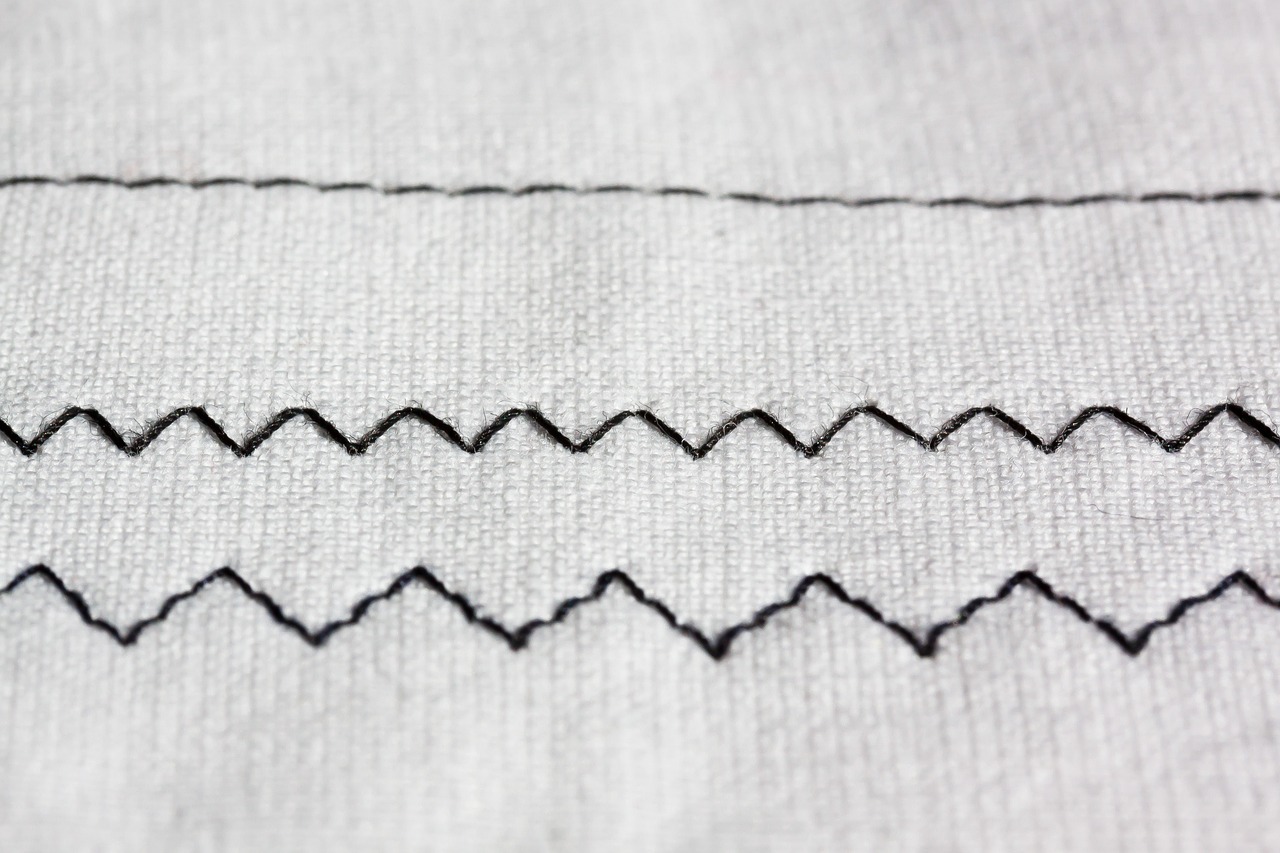

One of the most common problems sewists face is skipped stitches. This can be particularly frustrating when you're trying to achieve a perfect seam. Skipped stitches can occur for several reasons:

- The needle may be damaged or dull.

- The thread tension might be too tight.

- You could be using the wrong needle type for the fabric.

To tackle this issue, start by checking your needle. If it’s bent or worn, replace it with a new one that suits your fabric type. Adjusting the thread tension can also make a significant difference, so don’t hesitate to experiment a little until you find the sweet spot.

Another frequent issue is thread jams. These pesky occurrences can halt your sewing progress in an instant. Thread jams often happen in the bobbin area, and they can be caused by:

- Incorrect threading of the machine.

- A tangled thread in the bobbin case.

- Using low-quality thread that breaks easily.

To resolve a thread jam, first, turn off your machine and carefully remove the fabric and thread. Check the bobbin area for any tangled threads or debris and clean it out. Make sure to thread your machine correctly, following the guidelines in your manual. If you’re using lower-quality thread, consider upgrading to a better brand to reduce future issues.

Lastly, you might encounter issues with tension problems. If your stitches are looking uneven, it could be a sign that your tension settings need adjustment. Tension problems can manifest as:

- Loopy stitches on the underside of the fabric.

- Tight stitches that pucker the fabric.

To fix tension issues, consult your sewing machine manual for the correct settings for the type of fabric you’re using. Adjust the tension dial slowly, testing on a scrap piece of fabric until you achieve the desired stitch quality.

While many of these problems can be resolved at home, some issues may require professional help. If you notice persistent problems that you can’t seem to fix, it might be time to consult a technician. They can provide a thorough check-up and fix any underlying issues that might be affecting your machine’s performance.

To further assist you in your sewing journey, here are some frequently asked questions regarding sewing machine troubleshooting:

| Question | Answer |

|---|---|

| What should I do if my sewing machine won't start? | Check if it's plugged in and the power switch is on. Ensure the foot pedal is connected properly. |

| Why is my thread breaking? | This could be due to using the wrong type of thread, a damaged needle, or incorrect tension settings. |

| How often should I clean my sewing machine? | It's best to clean your machine after every few projects or at least once a month to prevent lint buildup. |

Common Problems and Solutions

Every sewist, whether you're a seasoned pro or just starting out, will inevitably encounter some common sewing machine problems. Understanding these issues and knowing how to resolve them can save you a lot of frustration and keep your projects on track. Let’s dive into some of the most frequent challenges you might face and their straightforward solutions.

One of the most prevalent problems is skipped stitches. This can happen for various reasons, such as using the wrong needle for your fabric type or having a dull needle. To tackle this issue, first, check if you're using the appropriate needle size and type. If you're sewing lightweight fabric, a smaller needle is ideal, while heavier fabrics require a larger needle. Additionally, make sure the needle is not bent or damaged; if it is, replace it immediately. Lastly, ensure that the thread is correctly threaded through the machine and that the tension settings are adjusted properly.

Another common issue is thread jams. Nothing is more frustrating than having your thread get stuck in the machine. This can occur due to tangled threads in the bobbin case or a misaligned needle. If you encounter this, stop sewing immediately to prevent further damage. Carefully remove the fabric and check the bobbin area for any snags or tangles. It’s often helpful to refer to your machine's manual for specific instructions on how to clear the jam. Regularly cleaning the bobbin area can also help prevent this issue from occurring in the first place.

Fabric bunching or puckering is another issue that many sewists face. This can happen when the fabric is not properly fed through the machine or if the tension is too tight. To fix this, check the feed dogs to ensure they are functioning correctly. If they appear to be stuck or not engaging, consult your manual for troubleshooting steps. Adjusting the tension settings can also help; a looser tension may be required for lightweight fabrics to prevent puckering.

Lastly, if your machine is making unusual noises, it could indicate a problem. Grinding or clunking sounds may suggest that the machine needs oiling or that a part is misaligned. Make sure to regularly lubricate your machine as per the manufacturer's instructions, and if the noise persists, it might be time to take your machine for a professional check-up.

In summary, being proactive about maintenance and familiarizing yourself with common problems can make a world of difference. Here’s a quick recap of some common issues and their solutions:

| Problem | Solution |

|---|---|

| Skipped Stitches | Check needle type and size; replace if necessary |

| Thread Jams | Clear bobbin area and re-thread the machine |

| Fabric Bunching | Adjust tension and check feed dogs |

| Unusual Noises | Oil the machine and check for misalignment |

By keeping these common problems and solutions in mind, you can enhance your sewing experience and tackle any issues that arise with confidence. Remember, every challenge is an opportunity to learn and improve your skills!

Q: How often should I clean my sewing machine?

A: It’s recommended to clean your sewing machine after every few projects or at least once a month, depending on usage. Regular cleaning helps prevent dust and lint buildup.

Q: What type of oil should I use for my sewing machine?

A: Always refer to your sewing machine’s manual for the recommended type of oil. Generally, a lightweight machine oil is ideal for most sewing machines.

Q: When should I consider taking my sewing machine to a professional?

A: If you encounter persistent issues that you cannot resolve, or if your machine requires complex repairs, it’s best to consult a professional technician.

Q: Can I use any fabric with my sewing machine?

A: While most sewing machines can handle a variety of fabrics, it's essential to use the correct needle and settings for different types of fabric to avoid issues.

When to Seek Professional Help

As much as we love our sewing machines and the joy they bring to our creative endeavors, there are times when even the most dedicated sewist needs to put down the tools and seek professional help. It's crucial to recognize when a problem is beyond your skill set or requires specialized knowledge. Ignoring these signs can lead to further damage, costing more time and money in the long run.

One of the primary indicators that it's time to call in a professional is when your machine exhibits persistent issues that you cannot resolve through basic troubleshooting. For instance, if you find that your sewing machine is consistently skipping stitches, even after changing the needle and re-threading, it may indicate a deeper mechanical issue that needs expert attention. Similarly, if you experience frequent thread jams or tension problems that seem impossible to fix, it might be time to consult a technician.

Another situation where professional help is warranted is when you notice unusual noises coming from your machine. Sounds like grinding, rattling, or excessive clicking can signal that something is amiss inside the machine. These noises often indicate that parts may be misaligned or worn out, which can lead to more significant damage if not addressed promptly. In such cases, a professional can diagnose the issue accurately and provide the necessary repairs.

Additionally, if your sewing machine has not been serviced in years, it might be a good idea to schedule a professional maintenance check. Just like a car, a sewing machine benefits from regular servicing to ensure all components are functioning correctly. A technician can clean internal parts, lubricate mechanisms, and replace any worn-out components, ensuring your machine runs smoothly for years to come.

Lastly, if you’ve recently purchased a vintage or second-hand sewing machine, it’s wise to have it inspected by a professional before using it extensively. These machines may have hidden issues that could lead to frustration or damage if not addressed. A professional can help you understand the machine's condition and provide recommendations for care and use.

In summary, while DIY maintenance is essential for keeping your sewing machine in good working order, knowing when to seek professional help is equally important. If you encounter persistent issues, unusual noises, or if your machine hasn’t been serviced in a long time, don’t hesitate to reach out to a qualified technician. Your sewing machine deserves the best care to keep your creative journey flowing smoothly!

- How often should I take my sewing machine for professional servicing? It's generally recommended to have your machine serviced at least once a year, or more frequently if you sew regularly.

- What are signs that my sewing machine needs professional help? Look out for persistent thread jams, skipped stitches, unusual noises, or if your machine hasn’t been serviced in a long time.

- Can I clean my sewing machine myself? Yes, regular cleaning is important and can be done at home, but some issues require professional attention.

- Is it worth getting a vintage sewing machine repaired? Yes, vintage machines can be valuable and worth repairing, especially if they have sentimental value or unique features.

Storing Your Sewing Machine

Proper storage is crucial for maintaining your sewing machine's condition and ensuring it remains a reliable companion for your sewing projects. Just like a car needs a garage to protect it from the elements, your sewing machine deserves a safe and clean space to rest when not in use. Without the right storage practices, you risk exposing your machine to dust, moisture, and even accidental damage. So, how do you store your sewing machine effectively? Let’s dive into some essential tips!

First and foremost, it’s important to keep your sewing machine covered. A dedicated sewing machine cover can shield it from dust and dirt that can accumulate over time. When selecting a cover, consider materials that are breathable and soft to prevent scratches. There are various types of covers available, from simple fabric ones to padded options that offer extra protection. If you don’t have a cover, a clean towel can serve as a temporary solution, just make sure it’s not too heavy, as that could trap moisture.

Additionally, you should store your machine in a dry, cool place. Avoid areas that are prone to humidity, such as basements or near windows where sunlight can cause overheating. A climate-controlled environment is ideal, as it helps prevent rust and other issues that can arise from fluctuating temperatures. If you live in a particularly humid area, consider using a dehumidifier in the room where your sewing machine is stored.

It's also essential to keep your sewing machine in an upright position. Storing it horizontally can lead to misalignment of internal components over time. If your machine has a removable extension table or other attachments, detach them before storage to save space and prevent accidental damage. You might also want to consider a dedicated storage cabinet or case that can keep everything organized and secure.

Lastly, don't forget about your sewing supplies. It's a good idea to store your threads, needles, and other accessories in a separate container or drawer. This not only keeps your workspace tidy but also prevents any items from getting tangled in the machine. Consider using a

| Supply Type | Recommended Storage |

|---|---|

| Threads | Thread box or organizer |

| Needles | Needle case |

| Bobbin | Bobbin holder |

| Foot Pedals | Storage bag or drawer |

By following these simple storage tips, you can ensure your sewing machine stays in top-notch condition, ready for your next creative endeavor. Remember, a little care goes a long way in prolonging the life of your beloved sewing machine!

Q1: How often should I clean my sewing machine?

A1: It's recommended to clean your sewing machine after every few projects or at least once a month, depending on usage. Regular cleaning prevents dust and lint buildup, ensuring smooth operation.

Q2: Can I store my sewing machine in a damp area?

A2: No, it’s best to avoid damp areas as moisture can lead to rust and damage. Store your machine in a dry, cool place for optimal protection.

Q3: Is it necessary to cover my sewing machine?

A3: Yes, covering your sewing machine helps protect it from dust and dirt, which can affect its performance over time.

Q4: Should I remove the needle when storing my machine?

A4: It’s a good practice to remove the needle to prevent any accidental damage or bending while the machine is stored.

Covering and Protecting

When it comes to maintaining the longevity of your sewing machine, one of the most overlooked aspects is how you cover and protect it when not in use. Just like a car needs a garage to shield it from the elements, your sewing machine deserves a cozy blanket to keep dust, moisture, and other potential hazards at bay. Think of your sewing machine as a delicate flower; without the right protection, it can wither away. So, let's dive into some effective ways to ensure your machine stays in pristine condition.

First and foremost, investing in a good quality sewing machine cover is crucial. A cover not only keeps dust away but also protects your machine from accidental bumps and scratches. There are various types of covers available on the market, ranging from simple fabric covers to more robust padded options. Here’s a quick breakdown of the different types:

| Type of Cover | Description | Benefits |

|---|---|---|

| Fabric Cover | A lightweight cover made of cotton or polyester. | Easy to clean and store, good for dust protection. |

| Padded Cover | A thicker cover with cushioning for added protection. | Excellent for preventing scratches and minor bumps. |

| Hard Case | A rigid case that encases the entire machine. | Ultimate protection from physical damage and moisture. |

Additionally, consider the environment where you store your sewing machine. A cool, dry place is ideal. Avoid areas that are prone to humidity or extreme temperatures, as these can affect the machine's internal components. If you live in a particularly humid area, you might want to include a silica gel packet in your storage area to absorb excess moisture.

Another important tip is to keep your sewing machine covered even when it's in use. This might sound counterintuitive, but covering the machine while you take breaks can prevent dust from settling on it during those short pauses. Just remember to remove the cover before you start sewing again!

Lastly, don't forget about the little things that can make a big difference. Regularly check the area around your sewing machine for any potential hazards. Ensure that there are no loose threads, pins, or fabric scraps that could accidentally get caught in the machine. Keeping your workspace tidy is just as important as covering your machine!

By following these simple yet effective steps, you can ensure that your sewing machine remains protected and ready for action whenever inspiration strikes. Remember, a well-cared-for machine not only performs better but also makes your sewing experience much more enjoyable!

- How often should I cover my sewing machine?

It’s best to cover your machine every time you finish using it, even for short breaks. - Can I use any fabric to make a cover?

While you can, using breathable fabrics like cotton is recommended to avoid trapping moisture. - What should I do if my sewing machine gets wet?

Immediately unplug it, dry it off, and let it air out before attempting to use it again.

Seasonal Maintenance Tips

As the seasons change, so do the needs of your sewing machine. Just like you might swap out your wardrobe from winter coats to summer dresses, your sewing machine requires a bit of seasonal TLC to keep it running smoothly. Each season brings its own challenges, from humidity to dust, and being proactive can save you a lot of headaches down the road. Let's dive into some essential tips to ensure your sewing machine is in tip-top shape, no matter the weather!

In spring, it's a great time to give your machine a thorough cleaning. After a long winter of sewing cozy projects, dust and lint can accumulate in the nooks and crannies of your machine. Make it a ritual to disassemble the bobbin case and feed dogs for a deep clean. Use a soft brush to remove any debris, and don't forget to check the needle plate for any hidden lint. This is also the perfect season to oil your machine, as the warmer temperatures can help the oil spread evenly.

As summer rolls in, the humidity can wreak havoc on your sewing projects and your machine. High moisture levels can lead to rust and other issues. To combat this, consider using silica gel packets in your sewing area to absorb excess moisture. Additionally, keep your machine covered when not in use to protect it from dust and humidity. If you notice your machine is running sluggishly, it might be time for a professional tune-up.

When autumn arrives, it’s time to prepare for the busy sewing season ahead, especially if you plan on making holiday gifts or decorations. Check your machine for any wear and tear on the parts, such as the needle and thread tension. A quick test of your stitches can help identify any issues before you start a big project. Also, consider organizing your sewing space to make it more efficient. A clean and organized area can significantly improve your sewing experience.

Finally, winter can be a cozy time to sew, but it also brings its own set of challenges. Cold temperatures can cause your machine's oil to thicken, which may lead to sluggish operation. To prevent this, ensure your machine is stored in a temperature-controlled environment. If you sew in a colder area, consider warming up your machine slightly before use. Additionally, keep an eye on your thread and fabric; cold air can create static, leading to tangles and snags.

In conclusion, a seasonal maintenance routine not only prolongs the life of your sewing machine but also enhances your sewing experience. By being mindful of the changing seasons and adjusting your maintenance practices accordingly, you can ensure that your sewing machine remains a reliable companion for all your creative endeavors.

Q: How often should I clean my sewing machine?

A: It's best to clean your machine after every few projects or at least once a month, depending on how frequently you sew. Regular maintenance helps prevent lint buildup and keeps your machine running smoothly.

Q: Can I use any oil to lubricate my sewing machine?

A: No, it's important to use sewing machine oil specifically designed for this purpose. Other oils can cause damage or leave residue that affects performance.

Q: What should I do if my machine is making strange noises?

A: Strange noises can indicate a problem. First, check for any obstructions or debris. If the noise persists, consult your manual or take your machine to a professional for servicing.

Q: How can I protect my sewing machine from dust?

A: Using a cover is an effective way to protect your machine from dust when it's not in use. You can also store it in a cabinet or dedicated space to keep it clean.

Q: Is it necessary to have my sewing machine serviced professionally?

A: Yes, regular professional servicing is recommended, especially if you notice any persistent issues. A technician can perform a thorough check-up and ensure your machine is in optimal condition.

Frequently Asked Questions

- How often should I clean my sewing machine?

It's best to clean your sewing machine after every project or at least once a month if you sew regularly. Regular cleaning prevents dust and lint buildup, ensuring smooth operation and prolonging the life of your machine.

- What tools do I need for cleaning my sewing machine?

Essential cleaning tools include a small brush, lint remover, and a suitable sewing machine oil. These tools help you reach those tricky spots and keep your machine in tip-top shape.

- Can I use any oil for my sewing machine?

No, not all oils are suitable for sewing machines. It's important to use a lightweight, specially formulated sewing machine oil to avoid damaging the internal components.

- What are some common mistakes to avoid when cleaning my sewing machine?

Some common mistakes include using too much oil, neglecting the bobbin area, and not cleaning under the needle plate. Avoiding these pitfalls can significantly enhance your cleaning routine.

- What should I do if my sewing machine is making strange noises?

If your machine is making unusual sounds, it could be a sign of a problem. First, check for any thread jams or debris. If the issue persists, it might be time to consult a professional technician.

- How can I tell if my sewing machine needs professional servicing?

If you encounter persistent issues that you can't troubleshoot, such as consistent skipped stitches or tension problems, it's best to seek professional help. They can provide the necessary repairs and maintenance your machine needs.

- What is the best way to store my sewing machine?

Always store your sewing machine in a cool, dry place and cover it with a protective cover to shield it from dust and moisture. This will help maintain its condition when not in use.

- Are there seasonal maintenance tips for my sewing machine?

Yes! During humid months, ensure your machine is kept dry, and in colder months, check the lubrication more frequently. Adapting your maintenance routine to the seasons can help keep your machine performing at its best.