The science behind pottery: Understanding the process

Pottery is not just about shaping clay; it’s an intricate dance of art and science that has captivated humanity for thousands of years. When you think about pottery, you might envision a potter deftly spinning a wheel, but there’s so much more beneath the surface. The journey from raw clay to a stunning ceramic piece is filled with fascinating processes, materials, and reactions that blend creativity with chemistry. In this article, we’ll dive deep into the world of pottery, exploring the fascinating science behind it, the materials involved, and the techniques that bring these beautiful creations to life.

Pottery has a rich history that dates back to ancient civilizations. It is one of humanity's oldest crafts, with origins that can be traced to various cultures around the globe. From the early days of hand-built clay vessels to the sophisticated techniques seen in modern ceramics, pottery has evolved significantly. The discovery of fired clay transformed everyday life, providing durable containers for storage and cooking. As we explore the history of pottery, we find that each culture has contributed unique styles and techniques, reflecting their values, environment, and technological advancements.

At the heart of pottery lies a variety of materials, each playing a crucial role in the final product. The primary component is clay, but it’s not just any clay; different types of clay offer unique properties that affect the outcome of the pottery. Glazes also play a significant role, providing not only color and texture but also protection to the ceramic body. Additionally, various additives can be mixed into the clay to enhance its workability and strength. Understanding these materials is essential for any potter aiming to create beautiful, functional pieces.

When it comes to pottery, not all clays are created equal. The three main types of clay used are earthenware, stoneware, and porcelain. Each type has its own characteristics and ideal applications:

- Earthenware: This is the most common type of clay, known for its porous nature and lower firing temperature. It’s often used for decorative pots and tiles.

- Stoneware: A durable clay that is fired at higher temperatures, stoneware is perfect for functional items like dishes and mugs.

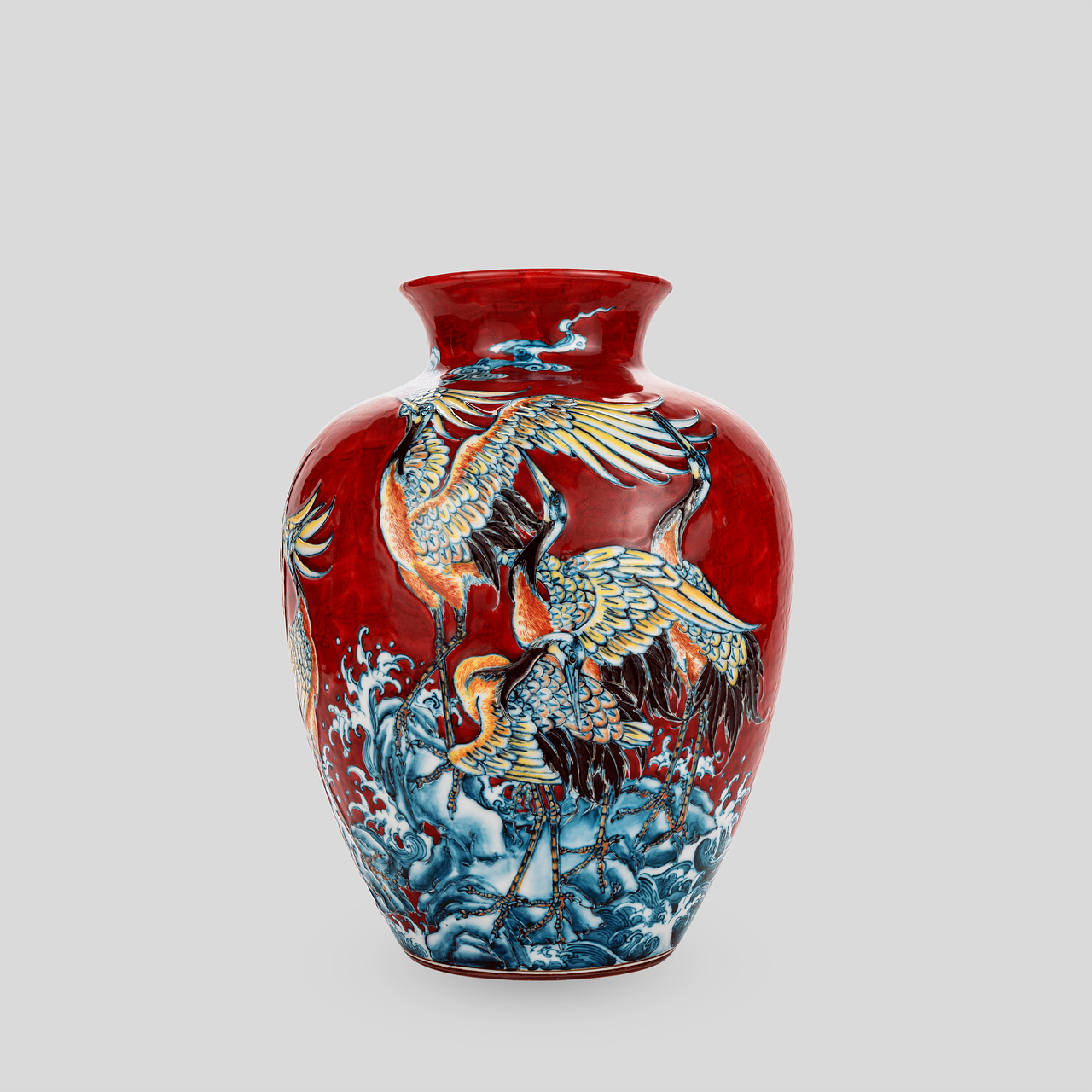

- Porcelain: Renowned for its fine texture and strength, porcelain is often used for high-end decorative items and tableware.

Earthenware is fascinating due to its porous nature, which means it can absorb water unless it is glazed. Typically fired at lower temperatures, around 1,830°F (1,000°C), this type of clay has been used for centuries, making it a staple in pottery. Its historical significance is immense, as it has been utilized for everything from ancient cooking vessels to modern art pieces. The warm, earthy tones of earthenware can evoke a sense of nostalgia, reminding us of simpler times.

On the other end of the spectrum lies porcelain, a clay that is fired at much higher temperatures, around 2,300°F (1,260°C). This high firing temperature gives porcelain its renowned durability and fine texture. It is often associated with elegance and refinement, making it a favorite choice for fine art pottery and delicate dinnerware. The ability to achieve a glass-like finish with glazes on porcelain is what makes it stand out in the world of ceramics.

Glazing is where the magic truly happens. It’s not just about adding color; it’s about enhancing the pottery's aesthetic and functional qualities. There are several techniques for applying glaze:

- Dipping: Submerging the piece in a glaze solution.

- Spraying: Applying glaze using a spray gun for an even coat.

- Brushing: Hand-painting glaze onto the surface for detailed designs.

Each of these techniques can dramatically affect the final look and feel of the pottery, allowing artists to express their creativity in countless ways.

Creating pottery is a multi-step process that requires patience and skill. It typically involves the following stages:

- Forming: Shaping the clay into the desired form, whether by hand or using a wheel.

- Drying: Allowing the piece to dry slowly to prevent cracking.

- Firing: Heating the clay in a kiln to harden it.

- Glazing: Applying glaze and firing again to achieve the final finish.

Each stage is crucial, and understanding the importance of each step can help potters achieve the best results.

When it comes to forming pottery, two primary techniques stand out: hand building and wheel throwing. Hand building allows for greater creativity and individuality, as artists can mold and shape the clay freely. Conversely, wheel throwing offers precision and uniformity, making it ideal for creating consistent shapes like bowls and vases. Each method presents its own set of challenges and benefits, influencing the final design and feel of the pottery piece.

Firing is where the transformation truly occurs. Different firing methods, such as oxidation, reduction, and raku firing, can significantly impact the final product. Oxidation firing occurs in a kiln with ample oxygen, resulting in bright colors. Reduction firing, on the other hand, limits oxygen, creating darker, richer hues. Raku firing involves removing pottery from the kiln while it’s still hot and placing it in combustible materials, leading to unique surface effects that are highly sought after.

At its core, pottery is deeply rooted in chemistry. The transformation of clay during firing is a chemical process that alters its structure, making it hard and durable. The interactions between clay and glaze during firing create a myriad of colors and finishes, showcasing the beauty of chemistry in art. Understanding these reactions can empower potters to experiment and innovate, pushing the boundaries of traditional pottery.

The mineral composition of clay plays a vital role in its behavior during firing. Different minerals, such as feldspar and kaolinite, influence how the clay reacts to heat, affecting its shrinkage, strength, and final characteristics. Knowing the properties of these minerals can help potters choose the right clay for their specific needs.

Glazes are not merely decorative; they are a complex blend of chemicals that interact during firing. The chemical components in glazes determine their color, texture, and finish. By understanding glaze chemistry, potters can create stunning effects and finishes that enhance their work, transforming a simple piece of pottery into a captivating work of art.

Q: What is the best type of clay for beginners?

A: Earthenware is often recommended for beginners due to its workability and lower firing temperature.

Q: Can pottery be both functional and artistic?

A: Absolutely! Many potters create pieces that serve a functional purpose while also being visually stunning.

Q: How can I learn pottery?

A: Consider taking a pottery class at a local studio, watching online tutorials, or experimenting at home with basic materials.

[The History of Pottery]

Pottery is not just an art form; it's a rich tapestry woven into the fabric of human history. The origins of pottery can be traced back to around 29,000 BC, with the discovery of the Venus of Dolní Věstonice, a figurine made from clay. This ancient artifact showcases the early human connection to clay and the potential for creativity. As civilizations evolved, so did the techniques and styles of pottery, reflecting cultural shifts and technological advancements.

Throughout history, pottery has played a crucial role in various cultures. For instance, the Chinese were pioneers in the development of porcelain during the Tang Dynasty (618-907 AD), creating pieces that were not only functional but also works of art. The intricate designs and high firing temperatures set Chinese pottery apart, influencing artisans across the globe. Similarly, the Greeks excelled in pottery, particularly during the Archaic and Classical periods, where their black-figure and red-figure techniques allowed for storytelling through imagery on vases and amphorae.

In Africa, pottery has deep cultural significance, often used in rituals and as a means of storytelling. The Berber tribes of North Africa, for example, have a rich tradition of hand-built pottery that reflects their unique heritage. The use of natural pigments and intricate designs showcases the connection between the potter and the land, emphasizing the importance of local materials.

As we look at the timeline of pottery, we can see that it has not only served practical purposes, such as storage and cooking, but also acted as a canvas for artistic expression. The evolution of pottery techniques can be categorized into several key periods:

- Prehistoric Pottery: Characterized by simple forms and utilitarian designs, often decorated with basic patterns.

- Ancient Civilizations: Cultures like the Egyptians and Mesopotamians advanced glazing techniques, creating more durable and aesthetically pleasing pieces.

- Medieval Pottery: In Europe, pottery became more refined with the introduction of stoneware, which was stronger and less porous than earthenware.

- Renaissance and Beyond: The revival of classical styles led to innovations in both form and decoration, giving rise to the ornate ceramics of the period.

In modern times, pottery has continued to evolve, incorporating new materials and technologies. The 20th century saw the rise of studio pottery, where individual artisans began to create unique pieces that blended functionality with artistic expression. Today, pottery is not only a craft but also a form of therapy and self-expression for many, allowing individuals to connect with their creativity and heritage.

In conclusion, the history of pottery is a fascinating journey that reflects the ingenuity and creativity of humanity. From its humble beginnings to its status as a revered art form, pottery has shaped cultures and continues to inspire artisans around the world.

Q: What is the oldest known pottery?

A: The oldest known pottery dates back to around 29,000 BC, with the discovery of the Venus of Dolní Věstonice, a figurine made from clay.

Q: How did pottery influence ancient cultures?

A: Pottery served practical purposes, such as storage and cooking, while also acting as a canvas for artistic expression, reflecting the beliefs and values of various cultures.

Q: What are the different types of pottery?

A: The main types of pottery include earthenware, stoneware, and porcelain, each with unique properties and uses.

Q: How has pottery evolved in modern times?

A: Modern pottery incorporates new materials and techniques, with a focus on individual artistic expression, leading to the rise of studio pottery.

[Materials Used in Pottery]

When it comes to pottery, the materials used are just as crucial as the techniques employed. Understanding these materials not only enhances the creative process but also significantly influences the final product's appearance and functionality. At the heart of pottery lies clay, which is the primary medium for sculpting and crafting. However, the journey from raw clay to a stunning ceramic piece involves a variety of components, including glazes and additives that contribute to the overall quality and aesthetic of the work.

Let's dive deeper into the different types of clay that potters use. Each type has its unique properties and ideal applications:

| Type of Clay | Characteristics | Common Uses |

|---|---|---|

| Earthenware | Porous, low firing temperature | Flower pots, tiles, and decorative items |

| Stoneware | Durable, medium to high firing temperature | Cookware, dinnerware, and functional pottery |

| Porcelain | Fine texture, high firing temperature | Fine art pottery, tableware, and figurines |

As you can see, each type of clay brings its own flavor to the pottery-making process. For instance, earthenware is known for its porous nature, which makes it excellent for decorative pieces but less suitable for functional ware that holds liquids. On the other hand, stoneware is celebrated for its strength and versatility, making it a favorite among potters who create functional items like bowls and mugs. Finally, porcelain, with its delicate and refined finish, is often used for high-end art pieces and fine dining sets, showcasing the potter's skill and creativity.

But clay isn't the only material to consider. Glazes play a pivotal role in pottery, providing not only color but also a protective layer that enhances durability. The glaze can transform a simple clay piece into a vibrant work of art. Different glazes can react uniquely during the firing process, resulting in a spectrum of colors and textures. Potters often experiment with various glazing techniques—such as dipping, spraying, or brushing—to achieve the desired effect. Each method can dramatically alter the final appearance of the pottery, adding depth and intrigue.

Moreover, additives are sometimes mixed with clay or glaze to modify their properties. For example, fluxes are added to lower the melting point of glazes, while colorants can introduce vibrant hues. These materials are essential for achieving specific effects, whether it’s a glossy finish or a matte surface. The chemistry behind these materials is a fascinating aspect of pottery that allows artists to push the boundaries of their craft.

In summary, the materials used in pottery are fundamental to the art form. From the choice of clay to the selection of glazes and additives, each decision impacts the final outcome. Potters must not only understand the characteristics of these materials but also how they interact during the firing process. This knowledge is what turns a simple lump of clay into a stunning ceramic masterpiece.

- What is the best type of clay for beginners? Earthenware is often recommended for beginners due to its workability and lower firing temperature.

- Can I use any glaze on any type of clay? Not necessarily. Each type of clay has specific glazes that work best with it, particularly concerning firing temperature.

- How do I know if my glaze will work with my clay? It's essential to refer to the manufacturer's guidelines for compatibility, as well as test small samples before committing to larger pieces.

[Types of Clay]

When it comes to pottery, understanding the types of clay is essential, as each type brings its own unique characteristics and possibilities to the table. Clay is essentially a natural material composed of tiny particles that can be molded when wet and become hard when fired. The three primary types of clay used in pottery are earthenware, stoneware, and porcelain. Each of these clays has distinct properties that not only affect the pottery's appearance but also its functionality and durability.

Earthenware is perhaps the most common type of clay used in pottery. It is known for its porous nature, which means it can absorb water and other liquids. This characteristic makes earthenware popular for creating decorative pieces and functional items such as pots and dishes. However, it does have a lower firing temperature, typically around 1,830°F (1,000°C), which means it is less durable than other types of clay. You might have seen earthenware in vibrant colors, often adorned with glazes that enhance its aesthetic appeal. Its historical significance is profound, as it has been used for thousands of years across various cultures, serving both practical and artistic purposes.

On the other hand, stoneware is a clay that is fired at a higher temperature, usually between 2,190°F (1,200°C) and 2,500°F (1,370°C). This higher firing temperature gives stoneware its strength and durability, making it ideal for functional pottery like dinnerware and cookware. Stoneware is typically non-porous, which means it doesn't absorb liquids, making it a practical choice for everyday use. It often has a more rustic appearance, with earthy tones and textures that can be enhanced through various glazing techniques. Many potters appreciate stoneware for its versatility and the range of artistic expressions it allows.

Now let’s talk about porcelain, the crème de la crème of pottery materials. Porcelain is known for its fine, smooth texture and its ability to be molded into delicate shapes. It is fired at extremely high temperatures, often exceeding 2,300°F (1,260°C), which results in a very strong and durable product. The beauty of porcelain lies in its translucence and ability to hold intricate details, making it a favorite among artists and collectors alike. Many people associate porcelain with fine china and high-end pottery, and it has played a significant role in the history of ceramics, especially in Asian cultures where it was perfected.

To summarize, here’s a quick comparison of the three types of clay:

| Type of Clay | Firing Temperature | Characteristics | Common Uses |

|---|---|---|---|

| Earthenware | 1,830°F (1,000°C) | Porous, colorful, lower durability | Decorative items, pots, dishes |

| Stoneware | 2,190°F - 2,500°F (1,200°C - 1,370°C) | Non-porous, durable, rustic appearance | Cookware, dinnerware |

| Porcelain | 2,300°F (1,260°C) and above | Fine texture, translucent, very strong | Fine china, artistic pottery |

Understanding these types of clay is crucial for anyone looking to delve into the world of pottery. Each type offers unique possibilities, so whether you're crafting a simple earthenware pot or an elegant porcelain vase, knowing your materials will help you create stunning pieces that reflect your artistic vision.

[Earthenware Characteristics]

When it comes to pottery, earthenware holds a special place in the hearts of artisans and collectors alike. Known for its porous nature, earthenware is a type of clay that has been used for thousands of years, dating back to ancient civilizations. Its ability to absorb water makes it unique, allowing it to be used in various applications, from functional kitchenware to decorative art pieces. The firing temperature for earthenware typically ranges from 1,830°F to 2,200°F (1,000°C to 1,200°C), which is lower than that of stoneware and porcelain. This lower temperature contributes to its characteristic softness and versatility.

One of the most fascinating aspects of earthenware is its historical significance. It has been the backbone of many cultures, serving as a medium for both practical items and artistic expression. The designs and glazes used on earthenware can vary widely, influenced by regional traditions and available materials. For instance, the vibrant colors found in Mexican talavera pottery are a testament to the rich cultural heritage associated with earthenware.

Moreover, earthenware is often adorned with various glazes that enhance its aesthetic appeal. These glazes can range from glossy to matte finishes, and they often incorporate a variety of colors and textures. The interaction between the glaze and the clay body during the firing process can produce stunning visual effects. However, it's essential to note that due to its porous nature, earthenware is not ideal for holding liquids without a proper glaze, as it can absorb moisture and lead to damage over time.

In summary, earthenware is not just a material; it is a canvas that tells the story of human creativity and ingenuity. Its affordable price and wide availability make it an excellent choice for both amateur potters and seasoned professionals. Whether you are drawn to its rustic charm or its rich history, earthenware remains a beloved choice in the world of pottery.

- What is earthenware used for? Earthenware is commonly used for pottery items such as dishes, pots, and decorative pieces due to its versatility and affordability.

- Can earthenware hold water? While earthenware can hold water, it is porous, so it requires a proper glaze to prevent leakage.

- How does earthenware differ from stoneware and porcelain? Earthenware is fired at a lower temperature than stoneware and porcelain, making it softer and more porous.

- Is earthenware safe for food use? Yes, as long as it is properly glazed and fired, earthenware can be safe for food use. Always check for food-safe labels.

[Porcelain Properties]

When we talk about porcelain, we’re diving into a realm of ceramics that truly stands apart from the rest. Known for its fine texture and remarkable durability, porcelain has been cherished for centuries, not just for its beauty but also for its functionality. It’s fascinating to think about how this material has evolved and how it continues to capture the hearts of artisans and collectors alike.

The journey of porcelain begins with its unique composition, which typically includes kaolin, feldspar, and quartz. These ingredients are carefully blended to create a clay body that is not only malleable but also capable of withstanding high temperatures during the firing process. The firing temperature for porcelain usually ranges from 1,200°C to 1,400°C, which is significantly higher than that of earthenware or stoneware. This high temperature is crucial, as it contributes to the porcelain's non-porous nature and its glass-like finish.

One of the standout characteristics of porcelain is its translucency. When held up to the light, high-quality porcelain exhibits a delicate glow, almost like a soft halo. This quality is what makes porcelain so desirable for fine dinnerware and decorative items. Imagine a beautifully crafted porcelain vase that not only serves as a stunning centerpiece but also allows light to dance through it, creating an enchanting atmosphere in any room.

In addition to its aesthetic appeal, porcelain is remarkably durable. It is resistant to chipping and scratching, making it an ideal choice for both functional and artistic pieces. Whether it’s a set of plates that have been passed down through generations or a modern sculpture that graces a gallery, porcelain stands the test of time. This durability is further enhanced by the vitrification process that occurs during firing, which transforms the clay into a hard, glassy material.

Moreover, porcelain is incredibly versatile. It can be used to create a wide range of items, from everyday dishes to intricate art pieces. This adaptability makes it a favorite among potters and artists who want to explore the boundaries of their creativity. For instance, artists can manipulate porcelain to achieve various finishes, including glossy, matte, or even textured surfaces, depending on their vision.

In summary, porcelain is not just a material; it’s a testament to the artistry and science of pottery. Its fine texture, high firing temperature, and durability make it a unique choice for both functional ware and fine art. Whether you’re sipping tea from a delicate porcelain cup or admiring a porcelain sculpture, you’re experiencing the rich legacy of a material that has captivated humanity for centuries.

- What is the difference between porcelain and stoneware?

Porcelain is fired at a higher temperature than stoneware, resulting in a denser, more durable product. Porcelain is also typically more translucent and has a finer texture.

- Can porcelain be used in the microwave?

Yes, most porcelain is microwave-safe, but it’s always best to check for any metallic decorations that could cause issues.

- How should I care for porcelain items?

To maintain porcelain, hand washing is recommended, especially for delicate pieces. Avoid using abrasive cleaners that can scratch the surface.

[Glazing Techniques]

Glazing is where the magic truly happens in the pottery-making process. It's not just about aesthetics; it’s a vital step that can significantly impact both the look and functionality of ceramic pieces. The way a glaze interacts with clay can create stunning visual effects and enhance the durability of the pottery. But what exactly are the different glazing techniques, and how do they influence the final product? Let’s dive into this fascinating aspect of pottery!

There are several methods potters use to apply glaze, each with its own unique characteristics and outcomes. The most common techniques include dipping, spraying, and brushing. Each method has its advantages and challenges, and the choice often depends on the desired finish and the specific piece being created.

Dipping is one of the simplest and most efficient methods. In this technique, the pottery piece is submerged into a container of glaze. This allows for an even coating and is particularly effective for larger pieces. However, it requires careful control to avoid drips and uneven thickness, which can lead to unpredictable results during firing.

Spraying offers a different approach. By using a spray gun, potters can achieve a fine mist of glaze that covers the surface evenly. This technique is fantastic for creating intricate patterns or gradients, but it requires a steady hand and a good understanding of the spray equipment. It’s also worth noting that the glaze must be thinned appropriately to ensure it can be sprayed effectively.

Then we have brushing, which is a more traditional and hands-on method. With this technique, potters apply glaze using a brush, allowing for detailed designs and the ability to control the amount of glaze applied. This method is excellent for adding decorative touches but can be time-consuming and may result in uneven coverage if not done carefully.

Ultimately, the choice of glazing technique can transform the personality of a piece. For instance, a piece that is dipped might have a smooth, uniform finish, while one that is brushed could showcase the texture of the brush strokes, adding depth and character. Understanding these techniques allows potters to experiment and create unique works of art that resonate with their personal style.

Moreover, the interaction between the glaze and the clay body during the firing process is crucial. Different glazes can react in various ways depending on the clay type, firing temperature, and atmosphere within the kiln. This is where the chemistry of pottery comes into play, as certain glazes will produce vibrant colors and textures when fired in an oxidizing atmosphere, while others may yield more muted tones in a reducing atmosphere.

In conclusion, glazing techniques are not just about applying color; they are an essential part of the pottery-making process that can elevate a simple clay form into a stunning piece of art. Each method offers unique benefits and challenges, and mastering these techniques allows potters to express their creativity fully.

- What is the purpose of glazing in pottery? Glazing serves both aesthetic and functional purposes, enhancing the appearance of the pottery while also providing a protective layer that makes it more durable and less porous.

- Can I use any glaze on any type of clay? Not all glazes are compatible with every type of clay. It's essential to match the glaze with the clay body to ensure proper adhesion and avoid defects during firing.

- How do I know which glazing technique to use? The choice of glazing technique depends on the desired effect, the size and shape of the piece, and your personal preference. Experimenting with different methods can help you find what works best for you.

[The Pottery Making Process]

The journey of transforming raw clay into exquisite pottery is a fascinating blend of art and science. It involves several crucial stages, each contributing significantly to the final product. From forming to glazing, every step is a dance of creativity and precision. So, let’s take a closer look at this intricate process that has captivated artisans for centuries.

First up is forming. This is where the magic begins! Potters can choose between various techniques to shape their clay. The most common methods include hand-building and wheel throwing. Hand-building allows for unique, organic shapes, while wheel throwing offers precision and symmetry. As the potter works the clay, they must pay attention to its moisture content; too dry, and it cracks; too wet, and it becomes unmanageable. It's like finding the sweet spot in baking a cake; just the right amount of ingredients makes all the difference!

Once the clay has been shaped, it goes through a crucial drying phase. This stage is essential because it prepares the clay for firing. The drying process can be tricky; if the clay dries too quickly, it can warp or crack. Potters often cover their pieces with plastic or damp cloths to slow down the drying process, ensuring a uniform moisture level. Think of it like letting dough rest before baking; it helps achieve the desired texture.

Next comes the exhilarating moment of firing. This is where the clay transforms from a fragile material into a durable ceramic. The first firing, known as biscuit firing, occurs at a lower temperature. This step hardens the clay and prepares it for glazing. After the biscuit firing, the pottery is often porous, allowing the glaze to adhere better. The excitement builds as potters prepare for the second firing, where the glaze is applied and the piece is subjected to high temperatures. This is where the true beauty of pottery is revealed!

During the glazing stage, potters apply a layer of glaze to their pieces. Glazing not only adds color and texture but also provides a protective coating. There are various glazing techniques, including dipping, spraying, and brushing. Each method yields different results, and potters often experiment with combinations to achieve unique finishes. It's like painting a canvas; the choice of colors and techniques dramatically impacts the final artwork.

After glazing, the pottery is ready for its final firing. This is where the chemistry of ceramics comes into play. As the kiln heats up, the glaze melts and interacts with the clay body, creating stunning effects. The temperature and atmosphere inside the kiln can drastically alter the final appearance of the pottery. Potters often use different firing methods, such as oxidation or reduction, to achieve specific results. It’s a thrilling moment when the kiln door opens, revealing the completed pieces, each a testament to the potter's skill and creativity.

In summary, the pottery-making process is a meticulous journey that combines artistic vision with scientific principles. From the initial forming to the final firing, each step plays a vital role in crafting beautiful ceramic pieces. Potters are not just artists; they are also chemists, engineers, and storytellers, each piece telling a unique tale of creativity and craftsmanship.

- What is the difference between earthenware, stoneware, and porcelain? Earthenware is porous and fired at lower temperatures, stoneware is durable and fired at higher temperatures, while porcelain is known for its fine texture and translucence, fired at the highest temperatures.

- How long does it take to make pottery? The time varies depending on the complexity of the piece, but generally, it can take anywhere from a few days to several weeks, considering drying and firing times.

- Can I make pottery at home? Absolutely! With some basic tools and materials, you can start your pottery journey at home. Many online tutorials can help you get started.

[Hand Building vs. Wheel Throwing]

When it comes to creating pottery, artists often find themselves at a crossroads between two primary techniques: hand building and wheel throwing. Each method offers unique benefits and challenges, catering to different styles and preferences in the world of ceramics. The choice between these techniques can significantly influence not only the final design of the pottery pieces but also the artistic experience of the potter.

Hand building is a technique that dates back thousands of years, allowing artists to craft pottery without the use of a potter's wheel. This method includes various approaches such as pinching, coiling, and slab construction. With hand building, potters can create organic shapes and intricate designs that may be more challenging to achieve on a wheel. It's akin to sculpting with clay, where the artist's hands become the primary tools. This technique is particularly popular among beginners, as it requires less specialized equipment and can be more forgiving for those still mastering their skills.

On the other hand, wheel throwing involves shaping clay on a rotating wheel, which can produce symmetrical and refined forms with speed and precision. This technique is often favored for creating functional ware, such as bowls and vases, where uniformity is key. The wheel allows potters to manipulate the clay efficiently, enabling them to create pieces that are both aesthetically pleasing and structurally sound. However, mastering the wheel can be quite challenging and requires a good amount of practice to achieve the desired results.

Both methods have their own distinct appeal. Hand building offers a sense of freedom and creativity, allowing potters to express their individuality through unique forms. Meanwhile, wheel throwing can be likened to a dance with the clay, where the rhythm of the wheel guides the potter's hands to create beautiful, balanced pieces. In fact, many artists choose to incorporate both techniques into their practice, combining the spontaneity of hand building with the precision of wheel throwing to create truly one-of-a-kind works of art.

Here’s a quick comparison of the two techniques:

| Aspect | Hand Building | Wheel Throwing |

|---|---|---|

| Technique | Crafting by hand using various methods | Shaping clay on a rotating wheel |

| Equipment | Minimal tools needed | Requires a potter's wheel |

| Skill Level | Accessible for beginners | Requires practice to master |

| Design Flexibility | Highly customizable and organic shapes | More uniform and symmetrical forms |

| Speed | Slower process, more deliberate | Faster production of similar pieces |

In conclusion, whether you choose hand building or wheel throwing, both techniques offer an enriching experience that can lead to stunning pottery creations. The decision ultimately comes down to personal preference, desired outcomes, and the artistic journey you wish to embark upon. So, why not try both? You might just discover a new passion along the way!

- What is the best technique for beginners? Hand building is often recommended for beginners as it requires less specialized equipment and allows for more freedom in design.

- Can you combine both techniques? Absolutely! Many potters use both hand building and wheel throwing to enhance their creativity and produce unique pieces.

- How long does it take to master wheel throwing? Mastering wheel throwing can take time and practice, with many potters spending months or even years honing their skills.

- What types of pottery can be made with each technique? Hand building is great for sculptural pieces and unique forms, while wheel throwing is ideal for functional items like bowls and mugs.

[Firing Methods]

Firing methods are a crucial aspect of pottery that significantly influence the final outcome of ceramic pieces. The process of firing transforms raw clay into durable pottery, and the choice of method can dramatically affect the clay's properties and the glaze's appearance. Among the most popular firing methods are oxidation firing, reduction firing, and raku firing. Each method has its unique characteristics and effects, making them suitable for different styles of pottery.

Oxidation firing is the most common technique used in pottery. This method occurs in an atmosphere where there is an ample supply of oxygen. The result is a bright, vibrant finish that enhances the colors of the glazes used. Potters often prefer oxidation firing when they want to achieve consistent results, as the process is more predictable. The firing temperature typically ranges from 1830°F to 2340°F (1000°C to 1280°C), depending on the type of clay and glaze being used.

On the other hand, reduction firing takes place in an oxygen-restricted environment. This method involves limiting the oxygen available during the firing process, which can create unique effects on both the clay body and the glaze. The result is often a more muted color palette, with deeper, richer tones. This technique is particularly popular in stoneware and is known for producing dramatic, earthy finishes. Potters who use reduction firing must carefully control the atmosphere within the kiln, as too much reduction can lead to undesirable results.

Raku firing is another fascinating technique that stands out due to its rapid firing process. In raku, pottery is removed from the kiln while it is still glowing hot and then placed into combustible materials such as sawdust or leaves. This creates a reduction atmosphere almost instantaneously and results in unique surface effects, including crackling and metallic sheens. Raku pottery is celebrated for its unpredictability, and each piece often turns out to be one-of-a-kind. However, it's essential to note that raku-fired pieces are typically not food-safe due to their porous nature and the potential for harmful materials from the combustible materials used.

To summarize, here’s a quick comparison of the different firing methods:

| Firing Method | Atmosphere | Typical Temperature Range | Characteristics |

|---|---|---|---|

| Oxidation Firing | Oxygen-rich | 1830°F - 2340°F (1000°C - 1280°C) | Bright colors, consistent results |

| Reduction Firing | Oxygen-restricted | 1830°F - 2340°F (1000°C - 1280°C) | Muted tones, earthy finishes |

| Raku Firing | Rapid reduction | Varies significantly | Unique effects, often non-food safe |

Understanding these firing methods is essential for any potter looking to create stunning ceramic art. The choice of firing technique can be likened to a chef selecting the right cooking method for a dish; it can make all the difference in the final presentation and flavor. So, whether you're aiming for the vibrant hues of oxidation or the earthy tones of reduction, mastering these methods will elevate your pottery to new heights.

- What is the best firing method for beginners? - Oxidation firing is often recommended for beginners due to its predictability and ease of control.

- Can I use the same glaze for different firing methods? - Some glazes are formulated to work in specific firing environments, so it’s essential to check the manufacturer's recommendations.

- Is raku pottery food-safe? - Generally, raku pottery is not considered food-safe due to its porous nature and the materials used in the firing process.

[The Role of Chemistry in Pottery]

The world of pottery is not just about shaping clay; it's a fascinating dance of chemistry and artistry. When you think about it, every time a potter spins clay on a wheel or molds it by hand, they're engaging in a complex chemical process that transforms simple earth into stunning works of art. This transformation is not merely physical; it involves intricate chemical reactions that dictate the final product's appearance, durability, and functionality.

At the heart of pottery lies the chemical composition of clay. Clay is primarily composed of minerals such as kaolinite, illite, and montmorillonite, each contributing unique properties to the clay body. For instance, kaolinite provides a smooth texture and is often used in porcelain, while montmorillonite offers plasticity, making it ideal for stoneware. Understanding these minerals is crucial because they influence how clay behaves during firing. When clay is heated, it undergoes a process known as sintering, where particles fuse together, resulting in a solid ceramic body.

Moreover, the interaction of glazes with the clay body is where chemistry truly shines. Glazes are composed of various oxides and minerals that melt during the firing process, forming a glassy surface. The chemistry behind glazes is quite intricate; for example, the presence of iron oxide can yield earthy reds and browns, while cobalt oxide creates vibrant blues. The firing temperature and atmosphere also play a significant role in determining the final color and finish of the glaze. In an oxidation atmosphere, glazes tend to exhibit bright, clear colors, while in a reduction atmosphere, they may develop deeper, more muted tones.

To illustrate the impact of chemistry on pottery, consider the following table that summarizes the effects of various minerals in glazes:

| Mineral | Effect on Glaze |

|---|---|

| Silica | Forms the glassy matrix in glazes |

| Alumina | Provides stability and prevents running |

| Sodium Oxide | Lowering the melting point, making glazes more fluid |

| Calcium Oxide | Enhances the glaze's durability and gloss |

As we delve deeper into the chemistry of pottery, we uncover the glaze chemistry. Each glaze's unique combination of materials can lead to a spectrum of colors and textures, influenced by factors such as firing temperature and the atmosphere in the kiln. For example, a glaze that appears green in a reduction atmosphere may turn a rich brown in oxidation. This transformative quality of glazes is what makes pottery an ever-evolving art form, where experimentation can lead to unexpected and beautiful results.

In summary, the role of chemistry in pottery is fundamental and multifaceted. From the mineral composition of clay to the intricate interactions of glazes during firing, understanding these chemical processes can elevate a potter's craft. It's like being a magician, where the right mix of ingredients and conditions can yield extraordinary results. So, the next time you admire a piece of pottery, remember that there's a whole world of chemistry behind its creation, making it not just a beautiful object, but a testament to the wonders of science.

- What is the most important mineral in clay? Kaolinite is often considered the most important mineral in clay due to its fine texture and suitability for porcelain.

- How does firing affect the color of glazes? Firing in different atmospheres (oxidation vs. reduction) can dramatically alter the colors of glazes due to the chemical reactions occurring during the process.

- Can I make my own glazes at home? Yes, many potters experiment with creating their own glazes by mixing various raw materials, but it requires a good understanding of glaze chemistry.

[Chemical Composition of Clay]

The chemical composition of clay is a fascinating topic that reveals much about its behavior during pottery making. At its core, clay is primarily composed of silicate minerals, which are rich in silicon and aluminum. These minerals form the backbone of clay's structure, influencing its plasticity, workability, and firing characteristics. The most common silicate minerals found in clay include kaolinite, illite, and montmorillonite, each contributing unique properties to the clay body.

To delve deeper, let's take a closer look at the primary components of clay:

| Mineral | Formula | Characteristics |

|---|---|---|

| Kaolinite | Al2Si2O5(OH)4 | Low plasticity, high firing temperature, often used in porcelain. |

| Illite | (K,H3O)(Al,Mg,Fe)2(Si,Al)4O10(OH)2 | Moderate plasticity, commonly found in stoneware. |

| Montmorillonite | (Na,Ca)0.33(Al,Mg)2Si4O10(OH)2·nH2O | High plasticity, excellent water retention, often used in earthenware. |

Besides these silicate minerals, clay also contains various fluxes and additives that can alter its firing temperature and final appearance. Fluxes, such as feldspar and boron, lower the melting point of the clay mixture, allowing it to vitrify more easily. This process is crucial for creating durable and functional pottery. Additives like grogs (pre-fired clay) can enhance the clay's strength and reduce shrinkage during firing, making it easier to handle and work with.

Moreover, the chemical reactions that occur during the firing process transform the clay's structure. As the temperature rises, the clay particles undergo a metamorphosis, losing moisture and chemically bonding to create a solid form. This transformation is not just physical; it is a complex interplay of chemistry that dictates the final properties of the pottery. The minerals present in the clay will react differently based on the firing atmosphere, leading to variations in color, texture, and strength.

In summary, understanding the chemical composition of clay is essential for potters who wish to master their craft. By manipulating the types of clay and additives used, artisans can create a wide range of pottery styles and functionalities. Whether it’s the fine elegance of porcelain or the rustic charm of earthenware, the chemistry behind clay is what brings these beautiful pieces to life.

- What is the most common type of clay used in pottery?

Kaolinite is often the most commonly used clay, especially for porcelain. - How does the firing temperature affect clay?

Higher firing temperatures generally lead to stronger and more durable pottery. - Can different clays be mixed?

Yes, potters often blend different clays to achieve desired properties.

[Glaze Chemistry]

When we talk about glaze chemistry, we're diving into a fascinating world where science meets art. The transformation of raw materials into stunning finishes on pottery is nothing short of magical. At its core, glaze is a glassy coating that is applied to ceramics, and its chemistry plays a crucial role in determining the final appearance and functionality of the piece. Understanding the chemical components of glazes can help potters create unique colors, textures, and finishes, making each piece a true work of art.

Glazes are primarily made up of three main components: silica, flux, and alumina. Silica is the backbone of glaze, providing the glassy structure. Fluxes are added to lower the melting temperature of silica, enabling it to melt and form a glassy surface during firing. Alumina, on the other hand, contributes to the stability of the glaze, preventing it from running off the pottery during the firing process. The balance of these components is essential, as it affects not only the melting point but also the durability and aesthetic qualities of the glaze.

Moreover, the interaction between these components can lead to a dazzling array of colors and finishes. For instance, adding metal oxides to the glaze can produce vibrant hues. Copper oxide can create rich greens and reds, while iron oxide can yield earthy browns and reds. Each of these oxides reacts differently at high temperatures, and the result can vary significantly based on the firing atmosphere—oxidation or reduction. This variability is what makes pottery such an exciting medium; a simple change in the glaze recipe or firing conditions can lead to unexpected and stunning results.

To illustrate the complexity of glaze chemistry, consider the following table that summarizes some common metal oxides used in glazes, their effects, and the colors they produce:

| Metal Oxide | Color Produced | Firing Atmosphere |

|---|---|---|

| Copper Oxide | Green (oxidation), Red (reduction) | Oxidation / Reduction |

| Iron Oxide | Brown, Red, Yellow | Oxidation |

| Cobalt Oxide | Blue | Oxidation |

| Manganese Dioxide | Purple, Brown | Oxidation |

In addition to these components, the firing temperature and atmosphere significantly influence the final outcome of the glaze. For instance, in a reduction atmosphere, where there is less oxygen available, copper oxide can turn from green to red, showcasing the dynamic nature of glaze chemistry. This interplay of elements makes every firing a unique experience, full of surprises.

Ultimately, mastering glaze chemistry allows potters to push the boundaries of their creativity. By experimenting with different combinations of materials and firing techniques, artists can achieve stunning effects that reflect their personal style. So, whether you're a seasoned potter or a curious beginner, understanding the science behind glaze chemistry can elevate your pottery-making experience to new heights!

- What are the main components of glaze? Glaze is primarily made up of silica, flux, and alumina.

- How do metal oxides affect glaze color? Metal oxides can produce various colors based on their chemical properties and the firing atmosphere.

- What is the difference between oxidation and reduction firing? Oxidation firing has ample oxygen, while reduction firing has limited oxygen, affecting the final color and finish of the glaze.

- Can I create my own glazes? Yes! Many potters enjoy experimenting with different materials to create unique glazes.

Frequently Asked Questions

- What materials are commonly used in pottery?

Pottery primarily uses various types of clay, such as earthenware, stoneware, and porcelain. Each type of clay has unique properties that affect the final product. Additionally, glazes and additives are employed to enhance both the aesthetic and functional qualities of the pottery.

- What is the difference between earthenware and porcelain?

Earthenware is known for its porous nature and lower firing temperature, making it ideal for decorative pieces. In contrast, porcelain is characterized by its fine texture and high durability, often used for fine art pottery and functional ware due to its strength and non-porous nature.

- How does glazing affect pottery?

Glazing not only enhances the visual appeal of pottery by providing color and finish but also serves as a protective layer. Different glazing techniques, such as dipping, spraying, or brushing, can create various effects, influencing the final aesthetic and functionality of the piece.

- What are the main steps in the pottery-making process?

The pottery-making process involves several key stages: forming the clay, drying it, firing it in a kiln, and applying glaze. Each step is crucial in determining the final quality and appearance of the ceramic piece.

- What are the benefits of hand building versus wheel throwing?

Hand building allows for greater creativity and individuality, as artists can shape their pieces without the constraints of a wheel. Wheel throwing, on the other hand, is often faster and can produce symmetrical forms more easily, making it suitable for functional pottery.

- How do firing methods impact pottery?

Different firing methods, such as oxidation, reduction, and raku firing, significantly influence the interaction between clay and glaze. These methods can alter the color and texture of the finished piece, showcasing the versatility of pottery.

- What role does chemistry play in pottery?

Chemistry is at the heart of pottery, influencing how clay transforms during firing and how glazes react with the ceramic body. Understanding the chemical composition of clay and glazes allows potters to predict and control the final outcomes of their work.

- Can I make pottery at home?

Absolutely! Many hobbyists create pottery at home using air-dry clay or by enrolling in local pottery classes. With the right tools and a bit of practice, you can explore your creativity and make beautiful ceramic pieces.